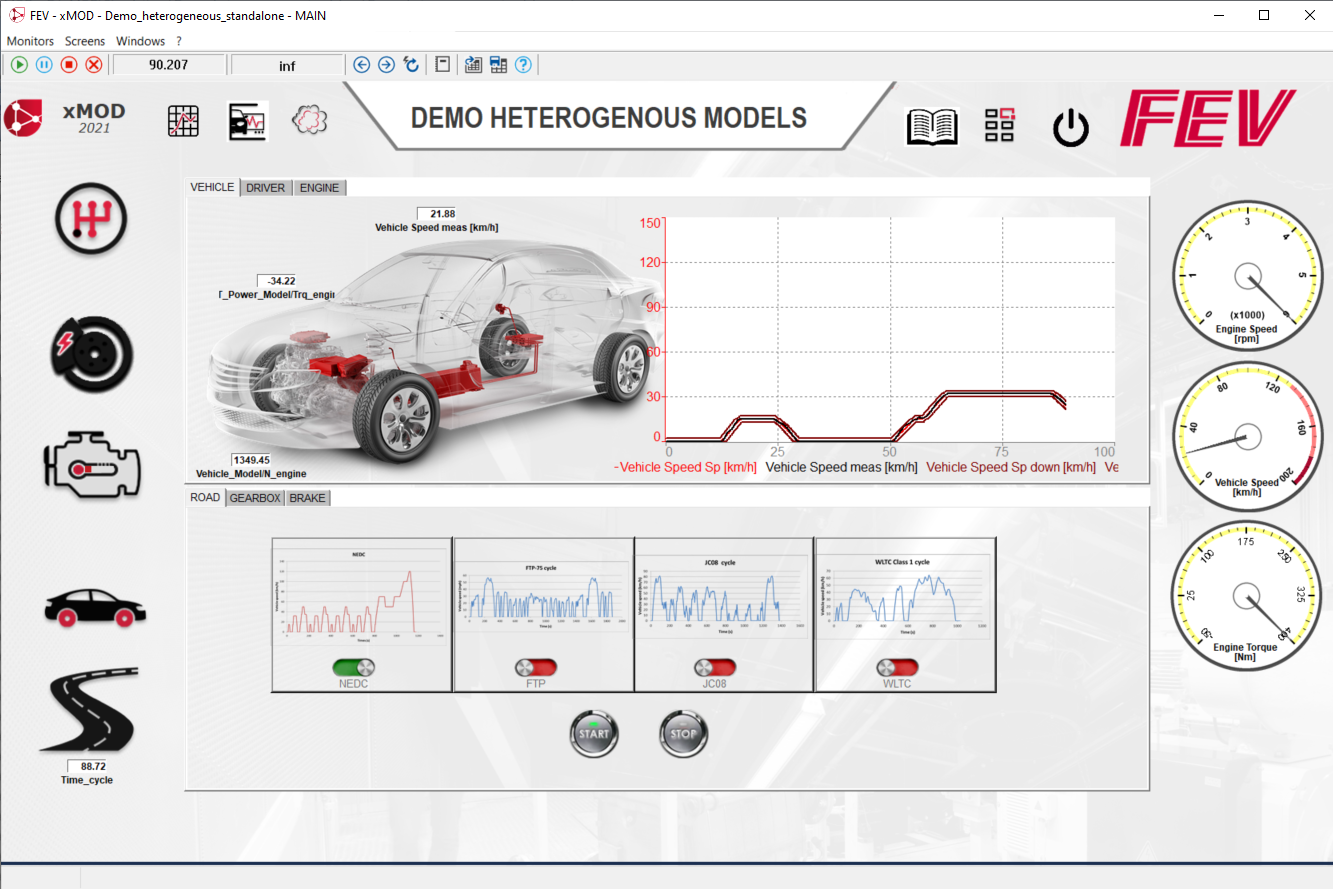

Exploit your models by giving them a new life: starting from the authoring tool, you can automatically create a vivid simulation with dedicated dashboards.

Multi-core, multi-solver and multi-rate execution to boost the performance of your simulations.

Extend simulation use to non-experts thanks to customizable user-friendly interfaces.

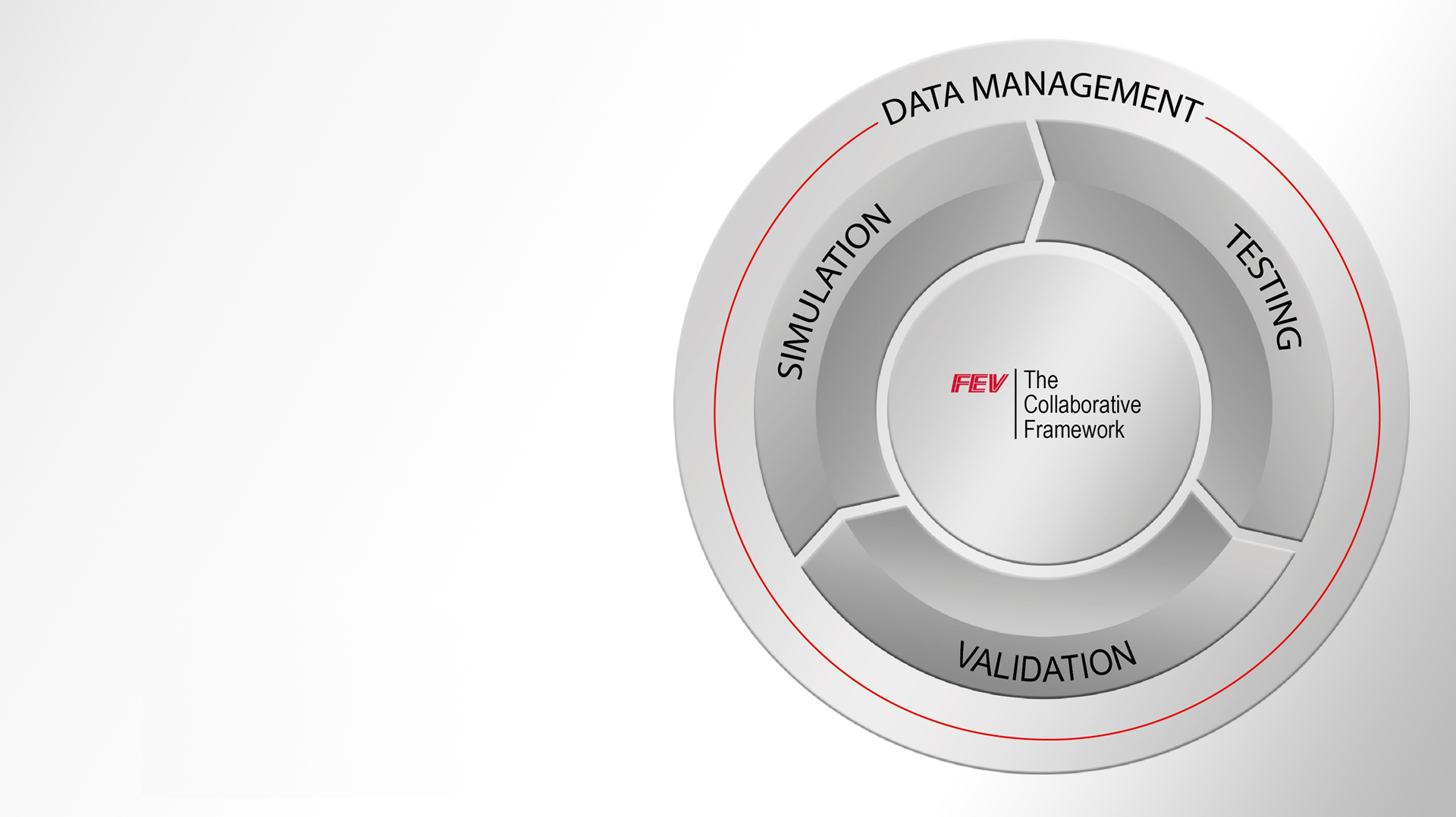

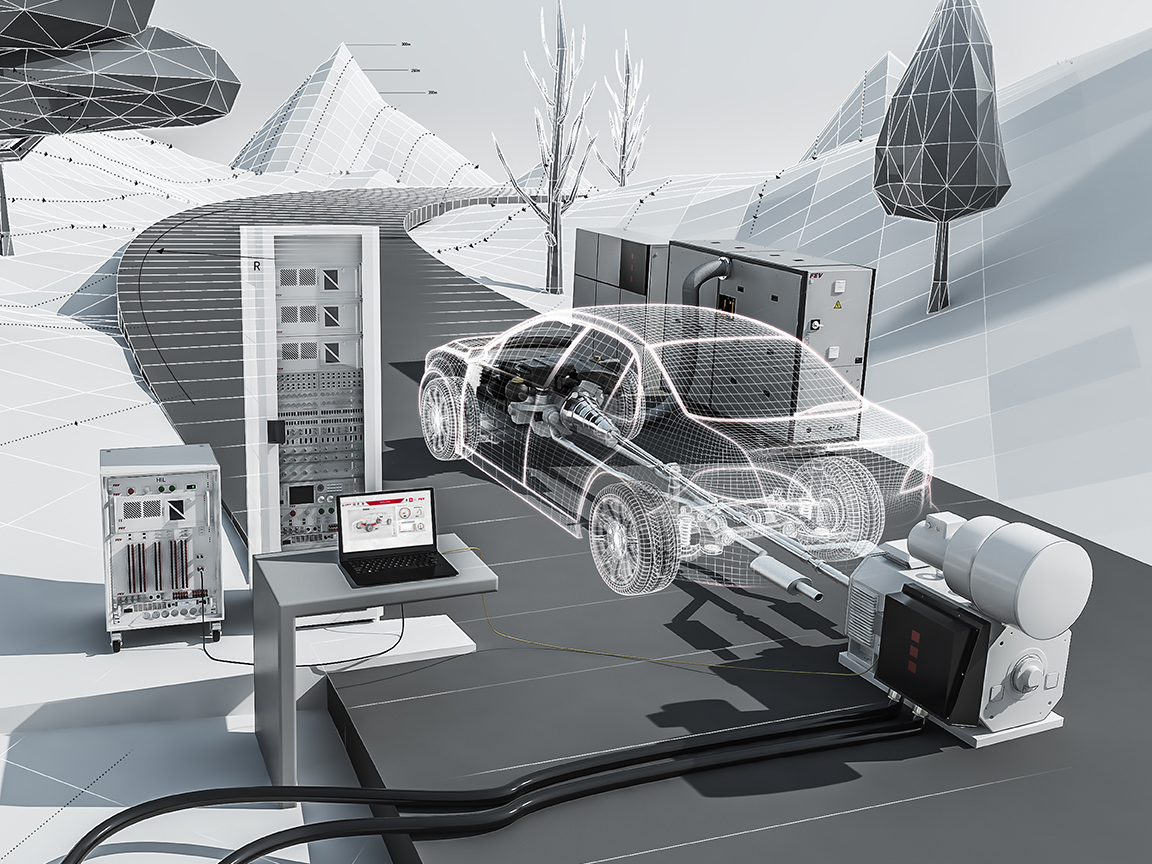

Exploit your models from the MiL phase until the HiL phase and take benefit from the FEV Collaborative Framework.

The challenge is to develop more complex powertrains in less time. It causes a rapidly increasing demand to powerful but also intuitive solutions.

FEV’s decades of experience in powertrain dynamics simulation and multi-body system simulation have been incorporated into a unique collaborative framework meeting today’s engineering needs.

With the FEV Collaborative Framework, the powertrain models are initially implemented at the desktop, then send and executed at the test rig in real time, combined with physical components. In a final step, the real powertrain is validated on the road. From beginning to end, the engineers stay in the same software environment: FEVFLEX for information management and MORPHEE for processing the tasks.

Many experienced simulation engineers prefer xMOD because of its ease of use and its flexibility.

xMOD provides a heterogeneous model integration environment for models built by different persons using different languages and tools and working within different entities.

Read more about the main features

xMOD is a simulation platform that adapts its interface to each engineering field: to be an expert in modeling is no longer necessary to run simulations!

The graphical user interface allows you to import your models and use your instruments by Drag’n’Drop.

Inside of xMOD you find highly optimized algorithms and advanced synchronization techniques based on Multi-threading and Multi-core processing.

This allows xMOD to execute models embedding different solvers at different step-times on multi-core architectures, enabling drastically speeding-up complex simulations execution.

IDAJ, our partner and official Japanese reseller creates a meeting around xMOD™!

Discover different topics around xMOD™ (In Japanese).

The appointment will be Friday, April 21 from 1:00 pm to 3:50 pm (JST : Japanese time).

The main topic will be “Frontloading and automating virtual calibration using xMOD”.

In this seminar, IDAJ proposes a solution to shift major calibration tasks to MiL / SiL / HiL environments. IDAJ and its partners will present several calibration use cases where this has been successfully done, explaining the benefits compared to conventional approaches.

Each topic will be discussed for 30 minutes, followed by a QA session of 5 to 10 minutes.

Programme:

13:00-13:40 (Presented by IDAJ)

Practical promotion method for virtual calibration - Handling of control and plant models and environment construction by xMOD

13:40 - 14:20 (Presented by IDAJ)

GT-SUITE as a plant model - The best multi-physics system simulation tool for virtual calibration

14:30-15:10 (Presented by Ono Sokki Co)

Building a test bench system on a PC. Introduction of the FAMS-R5 virtual mode for virtual calibration.

15:10-15:50 (Presented by IDAJ)

Proposal for building an optimisation system using xMOD, GT-SUITE, MATLAB/Simulink and Modelica

*The schedule is subject to change without notice. We would appreciate your kind understanding.

We are proud to announce the release of xMOD™ 2022 SP1 (3.5.3), new features:

Please see the ReleaseNote document for additional details. To download this release, you may download from our Download Center. If you do not have an account, you may request to establish one by registering on the web page or contact xMOD_Support@fev.com.